WHO we are

WHO we are Good Helper Business Consulting Co., Ltd., located in Shenzhen creative city. wiith unique local cultural background, professional knowledge, serious attitude, we are devoted to full services of quality control inspection, factory auditor, sourcing and trading; we are also offering a ONE-STOP import and export business solution and aiming to create value for our clients worl...

Innovative products are more than quality in pursuit of perfection

To help you ensure that your potential or existing suppliers...more

1.You book specific services 48 hours in advance and make pa...more

GHB is a one-stop sourcing/buying solution service company i...more

Years of accumulated experience in design and development in the field of electronics.

Providing you the most professional QC Service with the reasonable price, saving your quality cost,Sourcing the best goods in reasonable price.

No extra charge for inspections on Saturday & Sunday, No extra charge for travelling cost,the report we submit is professional and detailed.

GHI base on fairly, openly, equitably,each inspection manuscript must be signed by the head of the factory and QC to confirm in case of fraud, and then submit the inspection manuscript to client for reference.

We have strict evaluation,callback and bribery prevention system,Our service tenet Provide a professional service to every client.

Professional for you

Business development hand in hand with you and I go forward

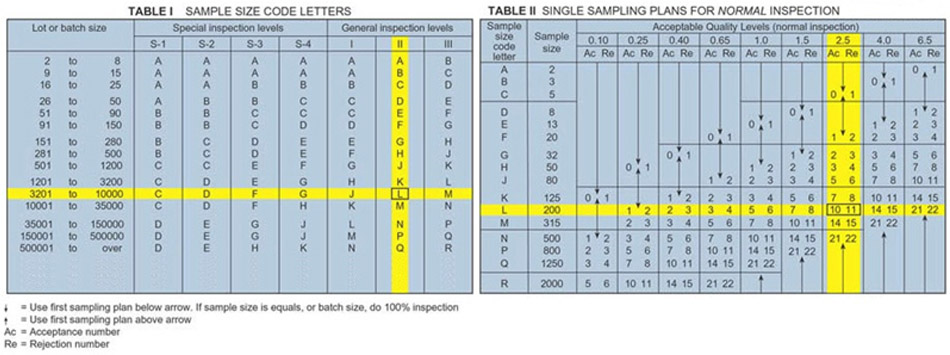

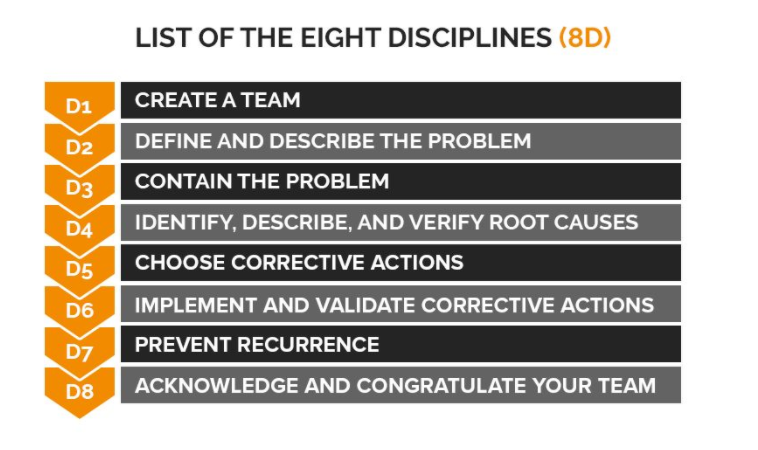

Quality issues often occur because the manufacturer has no control plan, the buyer has not defined good product specifications, and the factory’...

The Eight ‘8D Problem Solving Process’ Steps The 8D problem-solving process is team structured, consisting of 8 steps (or disciplines) whi...

Manufacturing your new product in China is a great idea, but legal protection is required There are numerous factories in China and beyond that can of...

The is split into 8 sections each corresponding to an element of the low-risk supply chain. Here's what we'll be covering: ...

What is Chinese New Year? Chinese New Year, or ‘Spring Festival’ to the Chinese, is the most important festival in China. It’s thei...

Exciting news! The Covid-19 vaccine from China UK to US are succeeding, and have passed Phase 2,which means so far everyone took it is safe from Covid...

Mobile:+86-18938943750 Telephone:+86-0755-25672741

Email:Service@goodhelper.biz